Tubes Filling Tshuab rau plasticlaminate thiab txhuas raj (txog 320 ppm)

KHOOM PLIG

Luv luv piav qhia ntawm yas raj sealing tshuab

1. Covyas raj sealing tshuabsiv Siemens 10-nti kov npo thiab Japanese Keyence PLC-KV8000 tswj software.

2. tube ntawm muab tub lim tswj qhov system servo ua haujlwm thiab cov lus tsa suab tswj logic

3. Tswj kev ua haujlwm: Tom qab lub raj raug tshem tawm lossis tso tawm, tseem muaj lub raj nyob hauv cov yeeb nkab txuas - kaw

4. Kev nyab xeeb muaj nuj nqi (tshem ceev thiab tiv thaiv kev hloov pauv) txhua lub qhov rooj sib cuam tshuam thaum lub raj ntawm cov muab tub lim tau khiav

5. tsis siv neeg raj filling tshuabmuaj Txhua lub tswb ntsuas tau piav qhia tuaj yeem hloov kho los ntawm kev tswj hwm vaj huam sib luag

6. Lub tshuab hluav taws xob servo ntawm lub raj ntawm cov muab tub lim tuaj yeem kho qhov ceev ntawm tus kheej, thiab qhov kev ceev ntawm tag nrho lub tshuab tuaj yeem hloov kho.

7. Cov cuab yeej inching ua haujlwm ntawm qhov ceev

8. Lub ntsiab vaj huam sib luag los kho txhua qhov chaw tsim khoom

9. Lub vaj huam sib luag ua haujlwm qhia txog qhov ntau lawm thiab cov kab ntau lawm

10. Raws li cov neeg siv khoom xav tau, teeb tsa ntau yam ntawm cov qauv rau lub raj ntawm cov muab tub lim

11. Covtsis siv neeg raj filling tshuabtswj vaj huam sib luag tuaj yeem teeb tsa cov haujlwm ua haujlwm

12. Lub tshuab raj tsis siv neeg puv tshuab muaj lub vaj huam sib luag ua haujlwm tiv thaiv los ntawm 3 qib kev ua haujlwm sib txawv.

13. Stainless hlau ywj siab hluav taws xob txee nrog cua txias, tiv thaiv qib nce mus txog IP65 lossis siab dua.Cov tais kab hluav taws xob nruab nrab ntawm cov khoom siv hluav taws xob thiab cov tshuab siv kaw cov tais, thiab cov kab hluav taws xob nkag los ntawm lub tshuab sab saum toj ntawm qib siab.

Nyob rau hauv lub neej yav tom ntej, kev tswj hwm tuaj yeem siv Siemens profitnet hloov cov ntaub ntawv mus rau MES thiab txuas nrog MES system.

Tubes Filling Tshuab rau plasticlaminate thiab txhuas raj

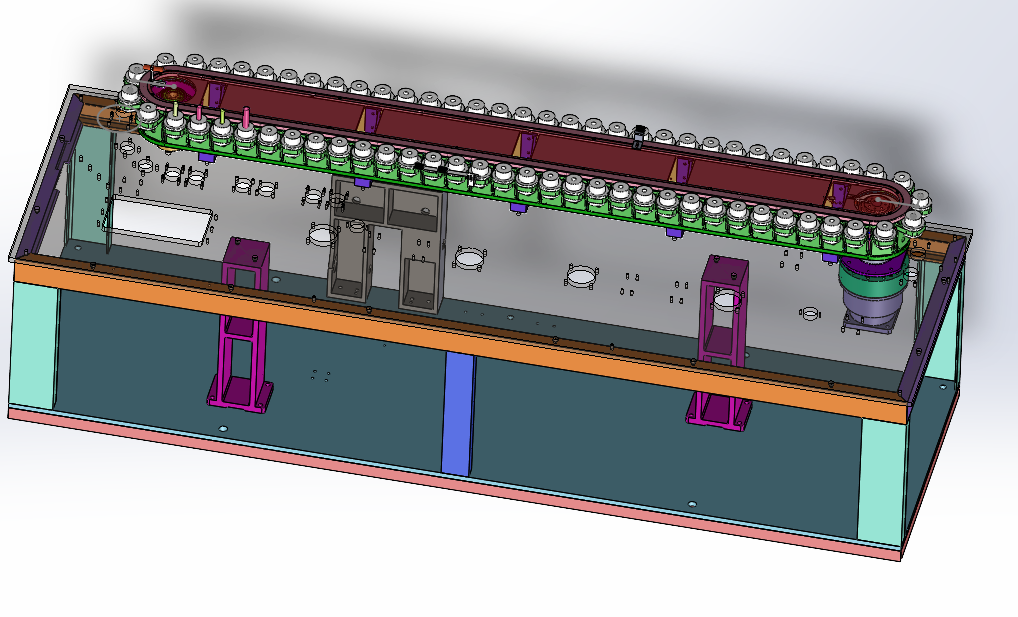

LFC4002Tubes Filling Tshuabyog plaub-chaw nres tsheb filling thiab sealing puv-servo yas raj sealing tshuab ntawm nws tus kheej tsim, tsim thiab tsim los ntawm peb lub tuam txhab.Nws yog tsim rau sau ntau yam specifications ntawm sterile los yog non-sterile aluminium-yas composite hlab, yas raj thiab txhuas raj.Tus tsim ceev yog 360 hlab / feeb, thiab qhov tseeb tshaj plaws ib txwm ceev ceev ntawm raj ntawm muab tub lim yog 250-340 hlab / feeb.Qhov tseeb filling yog ≤ ± 0.5%.Cov yeeb nkab txhuas yog kaw los ntawm folding sealing, aluminium-yas composite yeeb nkab yog kaw los ntawm cua kub los yog cua kub zaus, thiab cov yeeb nkab yas yog kaw los ntawm sab hauv sealing cua kub cua sov.

Tubes Filling Tshuab Lub ntsiab kis tau tus mob mechanism:

Tsis siv neeg raj filling tshuabtxais yuav cov hlau alloy steel ib qho kev qhia kev tsheb nqaj hlau, kev tiv thaiv kev vibration peb-cov kabmob raj lub khob tuav lub kaw lus, thiab cov txheej txheem ntawm 4kW servo intermittently tsav tube khob conveyor saw mechanism.Lub raj yas sealing tshuab txiav txim siab qhov siab tshaj plaws ceev thiab ruaj khov ntawm cov khoom ntim.

Tubes Filling Tshuab raj khob saw conveying ntaus ntawv muaj peb grooved sab sauv, qis thiab sab alloy steel qhia rails.Peb dov bearings yog ntsia rau ntawm lub raj lub khob lub rooj, thiab cov dov bearings txav directionally nyob rau hauv lub grooves thiab tsav lub hose.Tube khob saw tsis hnav.Kuj tseem muaj ob rab koob rau cov menyuam bearings mounted rau pins rau kev sib hloov.

yas raj sealing tshuab Lub hose conveyor saw hinges thiab kho lub raj lub rooj zaum (peb-bearing positioning, steel guide rail) rau ib leeg los ntawm ib tug toothed conveyor siv.Cov hniav siv conveyor siv nruj nruj raws li kev sib kis ntawm lub log tsav.Ib lub khob raj yog mounted ntawm txhua lub raj lub tog raj nplhaib.Lub khob raj yog ua los ntawm cov khoom siv POM thiab ua tau raws li cov qauv ntawm cov hose thiab cov qauv tsim.

Tubes Filling Tshuab conveyor saw overload tiv thaiv yog ua los ntawm keeb kwm rov qab precision synchronous torque limiter ntsia rau ntawm lub log, uas muaj lub neej ua haujlwm ntev.Yog hais tias cov yeeb nkab txuas yog daig, lub clutch raug txiav, qhov sib thooj hloov tau tshwm sim, thiab lub tshuab nres tam sim ntawd.

Tubes Filling Tshuab Online tu txheej txheem

1. Lub raj yas sealing tshuabfilling system thiab hopper tuaj yeem raug ntxuav los ntawm CIP chaw nres tsheb hauv lub voj kaw tib lub sijhawm.

2. Ua ntej pib CIP, lub filling nozzle yog nruab nrog ib lub khob CIP dummy, thiab cov kua ntxuav yuav raug tso tawm ntawm lub tshuab filling los ntawm cov kav dej txuas nrog CIP dummy khob.

3. Lub chaw ua haujlwm CIP (muab los ntawm cov neeg siv khoom) muab tus neeg saib xyuas tu rau qhov nkag ntawm lub hopper.Lub pob tsuag yog ntsia rau hauv lub tog raj kheej, thiab lub pob tsuag tsuag tsuag cov tshuaj ntxuav rau ntawm lub tog raj kheej sab hauv.Lub raj yas sealing tshuab filling tshuab yog tsim raws li cov qauv kev tu cev, thiab CIP ntxuav cov kua dej tuaj yeem ncav cuag txhua qhov chaw, cov kav dej thiab cov twj paj nruag uas tuaj yeem cuam tshuam nrog cov khoom thaum lub sijhawm tsim khoom.Tsiv cov khoom uas tuaj rau hauv kev sib cuag nrog cov khoom thaum lub sij hawm tsim khoom, xws li piston twj, agitators, thiab lwm yam., kuj yuav tig raws li thaum lub sij hawm CIP tu kom paub meej tias tag nrho cov nto ntawm lub tsiv qhov chaw yuav tsum tau ntxuav tag nrho.

4. Cov yeeb nkab txuas rau cov dej ntxuav kom rov qab mus rau cov neeg siv khoom CIP system (lub twj tso kua mis rov qab tsis suav nrog cov khoom siv)

5. Tsim kom muaj kev tu thiab tshuaj tua kab mob raws li cov neeg siv khoom xav tau, thiab txhua qhov kev tu thiab tshuaj tua kab mob tau teeb tsa hauv CIP chaw nres tsheb

6. Kev ntsuas kub, siab, ntws tus nqi thiab lub sijhawm ntawm CIP lub voj voog tuaj yeem tsim los ntawm CIP chaw nres tsheb raws li cov neeg siv khoom xav tau.

7. Lub filling nozzle ntawm lub raj yas sealing tshuab kuj tseem tuaj yeem raug tshem tawm sai sai ntawm lub twj tso kua mis rau kev ntxuav offline.

8.CIP tsheb yuav tsum 2T / H lossis siab dua

Tubes Filling Tshuab txais cov neeg hlau los pub cov raj (15x2 raj coj hauv ob kab txhua zaus, 9-12 zaug / feeb):

Raws li qhov programmed program, tus neeg hlau yuav siv ob kab ntawm cov hoses los ntawm lub thawv ruaj khov txhua lub sijhawm, hloov lawv mus rau sab saum toj ntawm lub khob raj, thiab tom qab ntawd ntxig lawv vertically rau hauv lub khob raj.Cov neeg hlau siv txoj kev txhawb nqa lub raj, thiab siv cov hlau tsis muaj steel kom nruj cov ntiv tes.Tsim, tuaj yeem raug tshem tawm rau kev ntxuav thiab tshuaj tua kab mob lossis tshuaj tua kab mob nrog tshuaj tsuag hydrogen peroxide

Lub grating pom seb puas muaj ib tug tubeleft nyob rau hauv tus neeg hlau tus ntiv tes uas tsis tau muab tso rau hauv lub khob raj, thiab activates lub extubation mechanism kom tshem tawm cov hose los ntawm tus ntiv tes, thiab ces mus rau lub raj.

LFC4002 Tubes Filling Tshuab muaj qhov zoo hauv qab no:

a.Kev tswj qhov system: Lub raj ntawm cov muab tub lim siv Siemens kov npo thiab Japanese Keyence motion controller, tag nrho servo tsheb npav tsav;lub suab nrov tsawg dua 75 decibels.

b.Indexing mechanism: raj ntawm muab tub lim siv lub servo system raws li lub indexer, thiab tsim txawv software kom lub dynamic rau static piv, lengthen lub zoo li qub lub sij hawm ntawm filling thiab sealing, thiab xyuas kom meej tias qhov ruaj khov ceev ntawm cov khoom yog siab tshaj 260pcs / min.

c.Khob chain guide rail: Lub tshuab raj tsis siv neeg puv tshuab txais kev ua haujlwm plaub-chaw nres tsheb, hlau alloy steel ib qho kev qhia kev tsheb nqaj hlau, thiab kev tiv thaiv kev vibration peb-cov kabmob raj lub khob tuav lub kaw lus.

d.Kev sib cais ntawm cov cheeb tsam: hose tus kheej tu, neeg hlau tube loading, servo nrov plig plawg raj loading, tsis siv neeg raj unloading, filling thiab sealing, servo raj tso tawm thiab lwm qhov chaw yog cais raws li GMP.

e.Pipe box positioning: Lub tshuab raj tsis siv neeg puv tshuab txais ob txheej kev thauj mus los.Lub thawv hose yog thauj rau ntawm txheej sab saud, muab tso rau ntawm lub platform inclined, thiab lub thawv khoob yog xa rov qab rau ntawm txheej qis.

f.Tube loading txoj kev: Neeg hlau lossis tube loading tshuab nkag mus rau hauv cov hlab, thiab tuaj yeem khaws 3000-4000 raj.

h.Servo benchmarking: mob xim xim cim ntes teeb liab, loj torque servo rotation positioning, kev kub ceev thiab stability.

i.Servo filling: Lub tshuab raj tsis siv neeg puv tshuab txais cov kab puv servo tsav thiab puv ceramic twj tso kua mis, uas yuav tsis hnav tawm.

j ib.Aluminium yeeb nkab clamping thiab flattening: Lub clamping thiab flattening mechanism ntawm tus Tsov tus tw sealing ntaus ntawv yog Ameslikas ib tug txiab hom clamping flattening, uas yuav yooj yim nias cua rau hauv lub raj.Tam sim no nws tau hloov mus rau txoj kab rov tav clamping thiab flattening mechanism, uas tsis muaj plua plav thiab tsis txhob tsav roj rau hauv lub raj.

k.Aluminium tube Tail sealing: Thaum sealing tus Tsov tus tw, lub folding thiab clamping adopts bearing-guided kab rov tav linear zog (keeb kwm ib tug arc pick-up hom) txav tsis rub lub raj upwards.Qhov no yog tshwj xeeb tshaj yog haum rau peb-fold tails.

n.Discharging ntaus ntawv: Lub servo ejects plaub-txoj kev hose thiab muaj ib tug rejection muaj nuj nqi.

o.Synchronous conveying: servo intermittent txav, cais trough conveying, zoo synchronization.

p.Pressure hopper: txais yuav hom qhib ceev ntawm cov yeeb nkab xa mus txuas rau lub twj tso kua mis.

q.Online CIP: Nws tuaj yeem ntxuav hauv online lossis offline.

Technical parameter

- Tubes Filling Tshuab Cov khoom siv tseem ceeb technical tsis

| No | parameter | lus hais | |

| Tube specification (mm) | Txoj kab uas hla 13 ~ 30, ntev 60 ~ 250 |

| |

| Xim cim qhov chaw (mm) | ± 1.0 |

| |

| Filling peev (ml) | 1.5 ~ 200 (Ua raws li 5g-50g specifications, specifications thiab ntau thiab tsawg raws li ntau yam thiab technology) |

| |

| Filling qhov tseeb (%) | ≤ ± 0.5 |

| |

| Sealing tails | Ob-fold, peb-fold, thiab eeb-shaped folds muaj. |

| |

| Cov zis muaj peev xwm PPm | 250-300 Nws |

| |

| Lub raj tsim nyog | Aluminium yeeb nkab Yas yeeb nkab Txhuas yas yeeb nkab |

| |

| Kev siv hluav taws xob (kW) | cev filler | 35 |

|

| Neeg hlau | 10 |

| |

| Hwj chim | 380V 50Hz |

| |

| cua siab | 0,6MPa |

| |

| Kev siv cua (m3/h) | 20-30 ib |

| |

| Transmission chain form | (Ntshuam los ntawm ltalis) Rebar synchronous siv hom (servo tsav) |

| |

| kis tau tus mob mechanism | Tag nrho servo tsav |

| |

| qhov loj (mm) | Length 3700 Dav 2000 Qhov siab 2500 |

| |

| Tag nrho qhov hnyav (kg) | 3500 | ||

Ntse zhitong muaj ntau tus kws tsim qauv, uas tuaj yeem tsimTubes Filling Tshuabraws li qhov xav tau tiag tiag ntawm cov neeg siv khoom

Thov hu rau peb kom pab dawb @whatspp +8615800211936

Cov khoom qeb

-

E-mail

-

Xov tooj

-

Sab saum toj

0086 15800211936

0086 15800211936